Though the proper use of personal protective equipment (PPE), which includes clothing, gloves, respiratory, eye and face protection devices, has been addressed in a previous newsletter, we’ve decided to revisit this topic due to its great importance in keeping you and your employees safe while on the job. Here are a few tips:

During Prep

When prepping a surface, sanding, removing dust, or using a solvent to clean a surface use a full face or half face cartridge respirator. Protective clothing, gloves, eye and face equipment should be used during all phases of application.

During Application

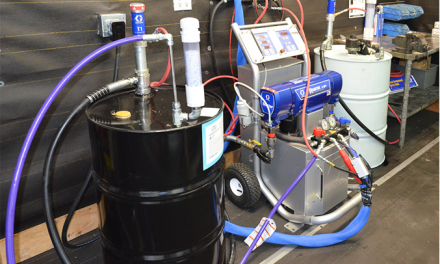

The same rules apply for PPE once you’ve moved on to applying polyurethane, polyurea, or any other solvent based products. You do, however, want to include the use of a fresh air supplied respirator. Since a fresh air mask covers the entire face, there is no need for additional safety glasses.

Stay Clean

Cleanliness is a must. When finished for the day, a quick cleaning of PPE should be performed.

Wipe respirators down with alcohol or spray-cleaner and store the cartridge in a large ziplock bag or sealed container. This will extend the life of your cartridges and keep them clean for their next use.

Remember…

The fresh air respirator supply pump has an intake and exhaust filter which should be checked regularly and replaced as needed.

Properly maintained and utilized safety equipment will prolong the lifespan of your respiratory system and limit potential health risks on the job. Stay up to code by periodically referencing your safety manual and visit the webstore to order new equipment.