Throughout my career I’ve asked hundreds of applicator-owners something that seems to be a simple question: What is the single most important document that comes into your office?

Responses run the typical range of usual suspects, number one is always the checks into the accounts receivable department. Close seconds are signed contracts, blueprints, bid invites, payroll, applications for payment and time-sheets. No one has ever given me the correct answer: daily job logs.

Why Are Job Logs Important?

Daily job logs are vital to the operation of your foam company because they are a true gauge of productivity, profitability and your break-even point. Job logs assist your staff in cultivating positive documentation habits of their day to day job activity.

This in turn helps you and your crew maintain expensive equipment, track costly material and supplies, assure customer satisfaction, give the true story of actual time and material versus planned time and material, lets you know which builders are properly accommodating your staff and tracks all vital manufacturer required information.

All this information is easily tracked in a document that takes less than 10 minutes to fill out per day. If you’ve ever been involved in a nasty job-site litigation you know this is 10 minutes a day very well spent.

Help the Manufacturer Help You

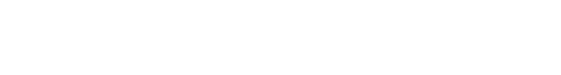

Our first step, if a contractor has a problem with our product not working as expected, is to call into their office to discuss the issue. Beyond getting a detailed account of what the issue is, there are a number of vital details that allow us to properly troubleshoot: lot numbers, batch numbers, outside temperatures, humidity, dew point, hose temp, machine temps, the last time screens and filters were changed, the size and pattern of spray tip being used, whether the lines were flushed out different types or different manufacturer materials.

If the contractor has no answers to these basic questions it makes it difficult for us to get in their corner and back them. These are the details we need to run our lab tests and ensure the best performance from our product.

Regardless of what hat I’m wearing; GC, inspector, architect, manufacturer or employer I’m going to be inclined to point at applicator error as the first cause of any job site failure. If proper job site documentation is not being maintained it’s difficult for any of those parties to take the applicator seriously. A true professional must protect themselves by taking 10 minutes out of their day to document that they’re doing things correctly, professionally and according to spec. If it’s your company, and your employees aren’t doing these reports, the person you are hurting most by not enforcing documentation is yourself.

Depend on Hard Facts and Clear Records

When I call an office that’s had an issue and I ask the basic questions I mentioned above, the response I get 95% of the time is that someone needs to check with the production manager to get the answers. In 20+ years doing this, I’ve honestly never met a production manager who knew any of this information. How could they? – they weren’t there. The correct response should be, “we need to check the job site log, let me have my sprayer text me a picture of that document right now and I’ll get it to you ASAP”.

Proper documentation, of anything related to the job site, employees, material and equipment, is critical in getting the support that you as an applicator deserve and look for. This documentation is what we as the manufacturer need to properly support you and your crew. By utilizing this simple document we can all better understand how your company runs and how our product works. This greater understanding and teamwork can only make us all more successful.

Rhino Linings Corporation is dedicated to your success. For more details on how to get started in the SPF industry, call 877.358.1320 or visit spf.rhinolinings.com

About the Author

Robert Quesnette is the Territory Sales Manager for the Northeast region. Robert has more than 25 years experience in the insulation industry. He founded and operated one of the first foam companies in Connecticut and has experience with client training, building science and code seminars.